Our commitment to a sustainable future

Since its creation, Geplast has placed environmental responsibility at the heart of its development. Reducing our environmental impact and promoting responsible practices throughout our production chain is a priority.

Aware of social, environmental and economic issues, Geplast has implemented a CSR policy. Our ambition is clear: to reconcile industrial performance with social responsibility, in order to contribute to development that is both sustainable and rooted in our local communities.

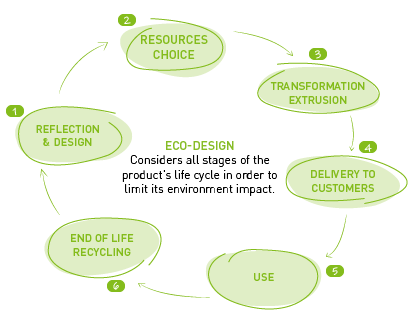

This approach is supported by the Geko brand, which promotes existing and future eco-design initiatives.

Our concrete commitments

Resource choices

As a matter of principle, and as far as possible, the material is never ‘primary’. All scraps are sorted, crushed and re-extruded. In addition to recycled material, Geplast also uses alternative composites, derived from virtually inexhaustible agricultural resources, or bio-based materials composed of 60% natural material, rice husks, also known as Loryza®.

Machine optimisation

Acquisition of a shredder and a crate tipper to improve the quality and quantity of recycled materials. Reduction of the carbon impact of our equipment through the installation of a water cooling system and improved vacuum production on our extrusion lines. Future investments in co-extrusion machinery.

Continuous improvement approach

Commitment to preventing the loss of industrial plastic pellets (GPI) into the environment. Geplast is actively committed to preventing the loss of GPI into the environment. The HSE department has studied and implemented a prevention approach covering the entire process from the arrival of the material on site to its recycling in accordance with the AGEC law.

Preparation of LCA data sheets

We conduct life cycle assessments (LCAs) on all our products in order to accurately assess their environmental impact and identify areas for improvement to reduce their ecological footprint. These analyses are then made available to our customers.

Biodiversity restoration

Since 2020, a partnership with Famille Mary has enabled two beehives to be installed near the shipping area, thereby contributing to the preservation of bees and the local ecosystem.

58%

of the PVC used in our

production comes from

recycled PVC, or 3, 390

tonnes per year.

40 %

products available for sale contain recycled materials.

EcoVadis: our CSR assessment

At Geplast, we have obtained EcoVadis certification, an international label that assesses companies’ CSR performance in four areas: environment, social, ethics and responsible purchasing.

This certification marks a key milestone in our eco-responsible approach. It validates the actions already taken within our company and encourages Geplast to continue its efforts to combine innovation, competitiveness and responsibility.

For us, being EcoVadis certified is a way of guaranteeing our customers, partners and employees that our CSR commitments are concrete, monitored and independently assessed.

MORE label

For the sixth consecutive year, Geplast has been awarded the first European label recognising our commitment to reducing the environmental footprint of our manufacturing processes by promoting the use of recycled raw materials.

Awarded by the Fédération de la Plasturgie et des Composites, the MORE (MObilized for REcycling) label demonstrates our progress in incorporating recycled materials into the production of our profiles.

Aware of the importance of reducing our carbon footprint for the good of the planet, we are committed to using as many recycled materials and so-called ‘renewable’ resources as possible in the manufacture of our products.