Indoor

Geplast Indoor, a range of profiles for interior design.

About Geplast

Expertise built on over 20 years’ experience and long-term commitments

Based in Sèvremoine in Maine-et-Loire, Geplast is a family business specialising in extrusion. For more than 20 years, we have been offering quality profiles and innovative solutions to professionals in the building and landscaping industries. We also offer tailor-made technical solutions.

Since September 2022, we’ve had expertise in the design and manufacture of injection moulds for the production of injection-moulded parts in polymers, PVC, ABS, biosourced materials, etc. This complete mastery of the design, development and production of injection-moulded parts and extruded profiles enables Geplast to meet specific customer requirements and diversify its offering by entering new business sectors.

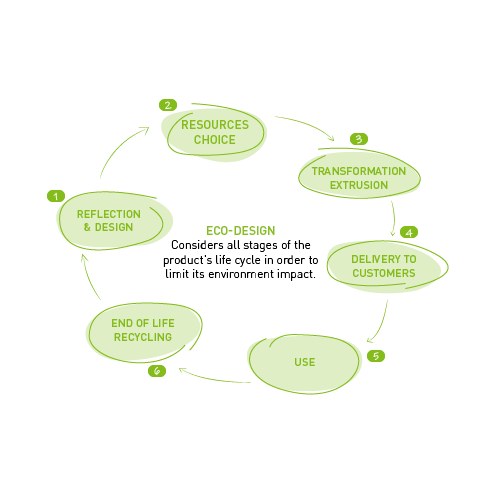

Since its creation in 2003, Geplast has been aware of the importance of reducing its carbon footprint. We are therefore working to offer products that are part of an eco-design approach.

Our company's core values are ethics, innovation, quality, sustainability and customer satisfaction.

Information requestAdvanced technical resources for high-performance production

1 profiling line, 2 filming lines, 30 extrusion lines, 50 tooling units designed every year.

An identity built on strong values

Well-being at work

Each of our employees benefits from optimal conditions to carry out their activity in complete serenity.

In-house training

Developing our internal talents is the surest way to achieve progress and continuous improvement.

The taste for innovation

Synonymous with autonomy, challenge and adventure, the taste for entrepreneurship has always been encouraged within Geplast.

Services & expertises

Geplast’s know-how and expertise are illustrated by the presence in its production unit of a tooling workshop and equipment at the cutting edge of innovation, a design office, a high-performance quality department…

Conception of the specifications

Conception of the specifications : The technical and innovation department is made up of specialists who support customers in drawing up their specifications and defining the product for any sector of activity.

These studies take into account all the technical and regulatory constraints, while respecting “eco-design” …

Read more

Creation of tooling

Creation of tooling : The design office, staffed by experts, is equipped with CAD/CAM tools to design toolings and moulds.

By investing in modern equipment such as a machining centre, wire EDM machines, a profiling machine…

Read more

Profile extrusion

Profile extrusion : Geplast has 30 extrusion lines

The machines can produce single, dual or tri-material profiles from 15 to 4,000 g. Divided up by field of activity, a first production centre is dedicated to the extrusion of our range of profiles…

Read more

Finishing

Finishing : With two in-house filming lines, Geplast is expanding its range of decors. More than 70 films are held in stock to meet the specific regional requirements and architectural trends of the market.

Since 2016, Geplast has acquired expertise in aluminium cladding (profile covered with aluminium film) …

Read more

Logistics

Logistics : Geplast provides its customers with the benefit of its logistical strength: regular delivery rounds throughout France and a 15,000 m² storage platform.

These facilities guarantee a high level of service, regardless of the delivery location…

Read more

Recycling

Recycling : Attentive to environmental concerns, Geplast recycles all its manufacturing waste in order to reduce its environmental footprint.

This approach includes the use of lead-free vinyl compounds in the manufacture of profiles…

Read more

An eco-responsible approach

Since its creation, Geplast has been aware of the importance of reducing its environmental footprint for the good of the planet. To achieve this, we make maximum use of so-called “renewable” resources to create innovative products that are part of a sustainable approach.

The GEKO project was therefore born out of a desire to create a visual identity to bring together all our current and future eco-design projects.

Geplast is recruiting

Employer brand for industryBecause Geplast is a unique collective human adventure, founded on a family history and strong values with local roots, it offers you real prospects for career development.